Popular Local Bakery Gets Delicious-Looking Caramel Concrete Floor

Polished Concrete Floor

About Wild Oats Bakery

In their own words, “Wild Oats is a locally-owned, from-scratch Bakery, Deli & Café in the heart of Brunswick’s Downtown and located at the Tontine Mall – an easy walk from Bowdoin College.” If you want to learn more about Wild Oats Bakery, the following link takes you right to their story: http://www.wildoatsbakery.com/about/

It was important for the bakery to choose just the right flooring for their location at 25 Burbank Avenue. This location is part of the great redevelopment of the Brunswick Navy Base. Hascall & Hall was asked to create an inviting environment for all the special customers who love and frequent their establishments. Wild Oats bakery selected a polished concrete floor in a beautiful deep caramel color. This flooring system was chosen not only for its beauty but also for its ability to withstand high traffic. More and more, Hascall & Hall sees retail establishments choosing polished concrete floors for their aesthetic appeal, durability and ease of maintenance.

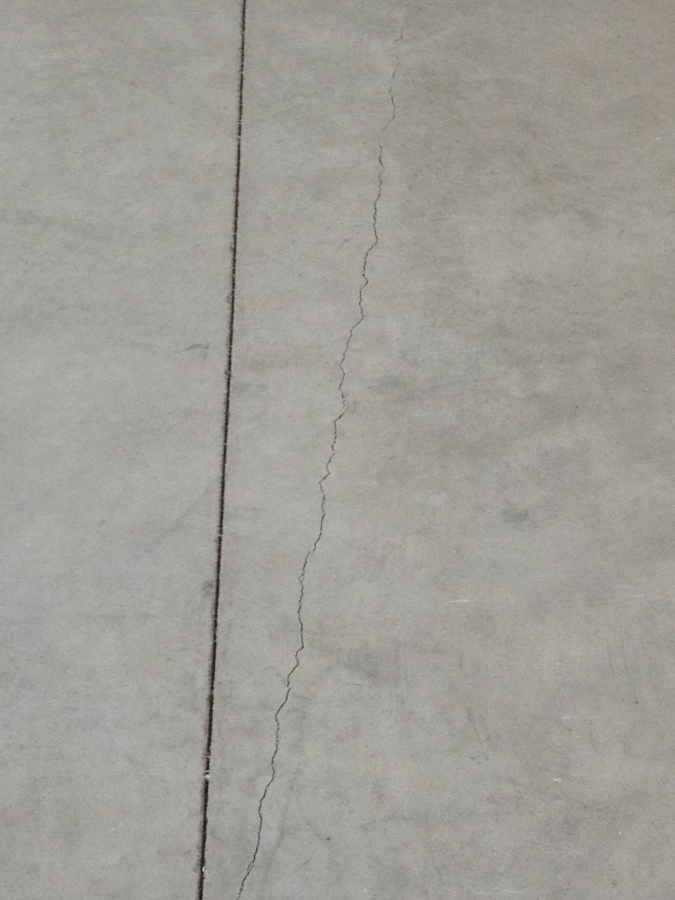

After the two rounds of diamond grinds, the Hascall & Hall team followed up with two additional grinds using resin pucks refining the floor each time in preparation for the stain.

The staining/dying process began and the crew used micro pads to ensure that the stain did not puddle leaving a ring pattern which took longer than usual due to the substrate issues. There was no way that we would have been able to make the substrate perfect without a very deep grind. The remaining steps in the polishing process were completed to reveal the new floor.

As we predicted, the floor did have a mottled look to it, but the expectations were set and Wild Oats Bakery loved the floor.

Location: Brunswick, Maine